In today’s energy-driven world, the demand for efficient and durable power transformers continues to grow. At the core of every reliable transformer lies a critical material—customized aluminum strip engineered for electrical windings. Precision-manufactured aluminum strips have become an essential choice for transformer producers seeking a balance of electrical efficiency, mechanical strength, and long-term performance.

At OUWEI, we focus on producing high-conductivity aluminum strips tailored specifically for power transformer windings. Through advanced rolling, slitting, and annealing technology, our aluminum products deliver exceptional electrical and thermal performance, ensuring stability and safety across a wide range of voltage applications.

What Is a Transformer Aluminum Strip?

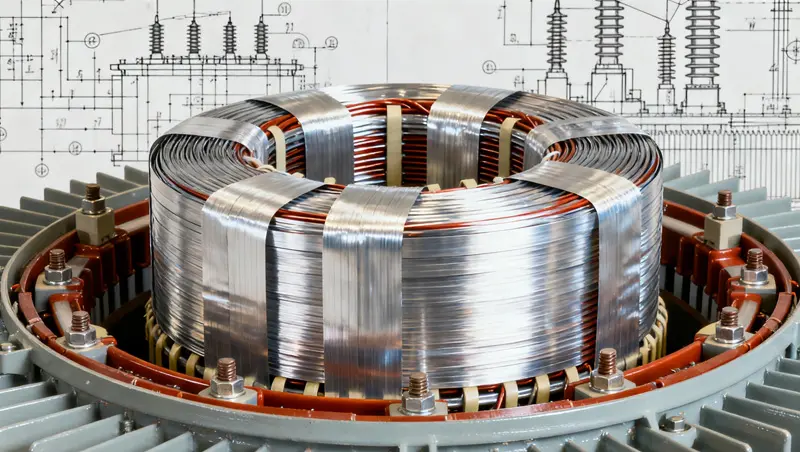

An aluminum strip is a narrow, flat section of rolled aluminum precisely processed to maintain uniform thickness and dimensional stability. For power transformer applications, these strips are produced from high-purity aluminum alloys and undergo additional refining to achieve the required mechanical and electrical properties.

Unlike standard aluminum sheets or plates, transformer-grade strips are designed to handle the demanding conditions of electrical windings. They feature smooth, oxide-free surfaces, accurate edges, and consistent grain structure—qualities necessary for the precise layering of transformer coils.

The manufacturing process typically involves cold rolling aluminum coils to specific gauges, followed by slitting to customized widths. These operations ensure that the final product provides the electrical conductivity, flexibility, and strength needed for modern transformer designs.

Why Aluminum Is Essential for Transformer Windings?

1. Excellent Electrical Conductivity

Transformer aluminum strip is typically made from high-purity aluminum alloys (such as 1060, 1070, and 1350), which contain more than 99.7% aluminum. This high purity gives the strip outstanding electrical conductivity, ensuring efficient current flow with minimal energy loss.

2. Lightweight and Cost-Effective

Compared to copper, aluminum has only about 30% of the density, which significantly reduces the total weight of transformer windings. This weight reduction not only lowers transportation and installation costs but also contributes to improved energy efficiency and overall equipment performance.

3. Superior Thermal Conductivity

Efficient heat dissipation is crucial in transformers to prevent overheating and insulation degradation. Aluminum’s excellent thermal conductivity allows the transformer to maintain stable temperatures during continuous operation, thereby extending its service life.

4. Outstanding Corrosion Resistance

When exposed to air, aluminum naturally forms a thin oxide film on its surface that resists corrosion. This makes aluminum strip highly suitable for outdoor transformers or units operating in humid or coastal environments.

5. Easy Formability and Processing

Transformer aluminum strip can be bent, wound, welded, or joined without compromising structural integrity. This process flexibility simplifies manufacturing and ensures tight, uniform coil winding, which is essential for compact and efficient transformer design.

Technical Specifications and Material Properties

Transformer-grade aluminum strip must meet strict international standards to guarantee consistent performance. Manufacturers follow specifications such as ASTM B209, EN 485, or GB/T 3190 to ensure product uniformity and quality.

Typical parameters include:

- Alloys: 1050, 1060, 1070, 1350 (99.5%–7% aluminum content)

- Temper: O (annealed), H12, H14, or customized

- Thickness Range: 0.10 mm to 3.0 mm

- Width Range: 10 mm to 1350 mm

- Surface Finish: Smooth, bright, oxide-free

- Edge Condition: Rounded or deburred for safe winding

These strips undergo precision rolling to achieve a uniform grain structure, ensuring both high conductivity and mechanical strength. Final annealing eliminates residual stress, giving the strip flexibility and elongation suitable for tight winding operations.

Application in Power Transformers

Transformer-grade aluminum strips are used in:

- Distribution transformers

- Power transformers

- Dry-type transformers

- Oil-immersed transformers

- Reactors and chokes

- Instrument transformers

In these applications, aluminum strip serves as the primary or secondary winding conductor, replacing traditional copper windings in many designs. Its combination of conductivity, thermal performance, and affordability makes it the material of choice for both medium and high-voltage systems.

Advantages of Using Aluminum Strips in Transformer Windings

- Energy Efficiency: Low resistivity and high conductivity reduce I²R losses, improving transformer efficiency.

- Mechanical Strength: Balanced elasticity prevents deformation during coil winding or thermal expansion.

- Thermal Stability: Maintains excellent performance under fluctuating load and temperature conditions.

- Lightweight Design: Simplifies installation and reduces transformer weight without sacrificing durability.

- Environmental Benefits: Aluminum is fully recyclable, supporting sustainable and eco-friendly manufacturing.

Customization and Processing Capabilities

One of the key strengths of aluminum strip production lies in its customization flexibility. Manufacturers can tailor alloys, thicknesses, widths, and surface finishes to match specific winding requirements.

Advanced rolling and slitting equipment ensures tight dimensional control, while edge finishing options—such as rounded or chamfered edges—prevent insulation damage during coil assembly. Strips can also be supplied with specific surface treatments or insulation coatings that improve bonding and dielectric strength.

This precision engineering guarantees that every strip performs consistently during winding, allowing manufacturers to optimize their transformer designs for performance, space efficiency, and cost savings.

Quality Assurance and Testing

Consistency is crucial in transformer winding materials. Each batch of aluminum strip undergoes comprehensive testing for mechanical and electrical properties, including conductivity, tensile strength, elongation, surface roughness, and oxide thickness.

Dimensional tolerances are verified to ensure accurate winding and stacking during assembly. Thermal and environmental tests simulate long-term operation, confirming that the strips maintain stability under electrical load, heat, and vibration.

Strict quality management systems and adherence to international standards ensure that every roll of aluminum strip meets the highest levels of reliability and performance required by transformer manufacturers worldwide.

Sustainability and Environmental Responsibility

Aluminum stands out not only for its technical performance but also for its environmental advantages. It is 100% recyclable and retains its physical properties indefinitely, making it a cornerstone material in sustainable transformer manufacturing.

Producing aluminum from recycled sources consumes only about 5% of the energy required to produce primary metal, significantly reducing carbon emissions and environmental impact. For industries pursuing green certification or eco-friendly production practices, aluminum strip provides a responsible and future-oriented solution.

Aluminum vs. Copper: Efficiency and Economics

While both copper and aluminum are used in transformer manufacturing, aluminum has become increasingly popular for its cost-effectiveness and performance balance.

| Property | Aluminum Strip | Copper Strip |

| Electrical Conductivity | ~61% IACS | 100% IACS |

| Density | 2.7 g/cm³ | 8.9 g/cm³ |

| Weight Reduction | ~70% lighter | Heavier |

| Corrosion Resistance | Excellent (forms oxide layer) | Good but may tarnish |

| Cost | Significantly lower | Higher |

| Recyclability | Excellent | Excellent |

In many modern transformer designs, aluminum strips provide similar performance to copper but at a much lower cost and weight, making them ideal for large-scale production and energy-efficient systems.

The Future of Transformer Aluminum Strips

As the global energy sector evolves, the role of aluminum strip in power transformer production will continue to expand. The industry’s move toward lightweight, high-efficiency, and recyclable materials makes aluminum an ideal conductor for the next generation of electrical equipment.

Emerging technologies in smart grids, renewable energy integration, and high-voltage direct current (HVDC) systems further reinforce the need for materials that balance performance with sustainability. Aluminum’s versatility and recyclability position it as a key enabler of these innovations.

Conclusion

Transformer-grade aluminum strip represents the perfect fusion of conductivity, strength, efficiency, and environmental responsibility. Its exceptional balance of electrical and thermal performance ensures that transformers operate safely, reliably, and efficiently over decades of service.

Through advanced manufacturing and strict quality control, producers of customized aluminum strip for transformer windings deliver materials that meet the highest global standards. In an era defined by electrification and sustainability, aluminum strip stands as the material of choice—empowering the energy systems that power our world.