An oil‑filled transformer is a type of power transformer where the core and windings are immersed in a specially selected insulating oil. The oil serves two main functions: cooling the internal components and providing electrical insulation. This type of transformer is commonly used in high-voltage applications, where it offers significant advantages in both efficiency and performance.

In this article, we will explore how oil‑filled transformers work, their key features, types, and advantages, and how they compare to dry‑type transformers. We will also cover common applications, the oil-filling procedure, and best practices for maintenance.

How an Oil-Type Transformer Works?

The basic operation of an oil‑filled transformer follows the same electromagnetic principles as any other transformer. Alternating current in the primary winding creates a changing magnetic field in the core, which induces a voltage in the secondary winding. The critical difference in an oil‑filled transformer is the presence of the insulating oil surrounding the core and windings.

Here’s how it works:

The windings and core generate heat during operation due to core losses (hysteresis and eddy currents) and copper losses (resistive heating in the windings).

The insulating oil absorbs this heat and helps cool the internal components. Depending on the design, the oil may circulate naturally through convection or with the help of radiators and fans to enhance cooling.

The oil also acts as a dielectric medium, preventing electrical arcing between the windings and core, thus ensuring the transformer’s safe and efficient operation.

In some designs, oil circulation is enhanced by external cooling mechanisms, such as radiators or fans, which further aid in dissipating heat into the environment.

This structure allows oil‑filled transformers to handle larger power ratings and higher voltages than dry‑type transformers.

Key Features, Types, and Advantages

Features & Benefits

Oil‑filled transformers have several important features that make them ideal for heavy-duty applications:

Enhanced Cooling: The oil allows better heat dissipation than air alone, enabling the transformer to manage higher power loads. This makes them suitable for use in high-capacity applications.

Electrical Insulation: The oil serves as an excellent dielectric medium, improving the insulation between the windings and core, which helps prevent short circuits or arcing.

Longer Lifespan: With proper maintenance, oil‑filled transformers often have longer operational lives compared to their dry‑type counterparts.

Types

Oil‑filled transformers can be classified in several ways, including by application, phase configuration, and cooling method. Here are the common types:

By Application: Oil‑filled transformers are primarily used in power generation, distribution networks, and industrial applications. They can be classified as power transformers (for large voltage steps) or distribution transformers (for stepping down voltage for residential or commercial use).

By Phase: Oil‑filled transformers can be either single-phase or three-phase. Three-phase units are typically used for larger capacities, while single-phase transformers are more common in residential and small-scale applications.

By Cooling Method: Transformers can be designed for different cooling methods, such as ONAN (Oil Natural Air Natural), ONAF (Oil Natural Air Forced), and OFAF (Oil Forced Air Forced). The cooling system can affect the transformer’s efficiency and size.

Oil-Filled vs Dry-Type Transformers

When deciding between an oil‑filled transformer and a dry‑type transformer, it is important to understand the differences in their cooling methods, power ratings, fire risk, and environmental concerns.

Cooling: Oil‑filled transformers generally offer better cooling because the oil transfers heat more efficiently than air, allowing for larger power ratings. Dry‑type transformers rely on air for cooling and are typically used for smaller ratings or where fire safety is a concern.

Insulation: Oil serves as an excellent electrical insulator, whereas dry‑type transformers use solid insulation materials. This makes oil‑filled transformers more efficient for high-voltage applications.

Fire Safety: Dry‑type transformers have an advantage when it comes to fire safety since they do not use flammable oil. However, oil‑filled transformers are often used in outdoor or controlled environments where fire risk can be mitigated.

Maintenance: Oil‑filled transformers require regular checks on oil levels, oil quality, and potential leaks, while dry‑type transformers generally require less maintenance.

Typical Applications

Oil‑filled transformers are commonly used in several critical industries due to their high power capacity and cooling efficiency:

Power Generation and Substations

Oil‑filled transformers are used to step up or step down voltages in power plants and substations, where they handle high power loads and operate under extreme conditions.

Industrial Facilities

Heavy industries, including manufacturing plants and mining operations, use oil‑filled transformers to manage large electrical loads and ensure continuous power supply.

Rural or Remote Installations

In rural areas or locations where space is not a major concern, oil‑filled transformers provide a robust solution for power distribution, especially when larger loads are required.

Oil-Filling Procedure & Maintenance Best Practices

Proper oil filling and ongoing maintenance are crucial to ensure the reliability and longevity of oil‑filled transformers.

Oil‑Filling Procedure

The oil-filling process is a critical step in ensuring the transformer’s safety and performance.

The key steps include:

- Preparation: Before filling the transformer with oil, ensure that the tank is free from damage, and all seals are in good condition. It is also essential to ensure the transformer is disconnected from the power source and properly grounded.

- Vacuuming: One of the best practices is to evacuate the transformer’s tank to remove air and moisture before introducing oil. This process ensures that the transformer is free from contaminants and air pockets that could interfere with its insulation properties.

- Filling: Oil should be added slowly and evenly to prevent air entrapment, which can lead to hot spots and reduce the transformer’s efficiency. In some designs, oil is introduced from the bottom of the tank to ensure proper circulation.

- Testing: After filling, the transformer’s oil should be tested for dielectric strength and moisture content to ensure it meets the required standards.

Ongoing Maintenance

Routine maintenance helps extend the lifespan of oil‑filled transformers.

Some important maintenance tasks include:

- Checking Oil Levels: Ensure that the oil levels are consistently within the recommended range.

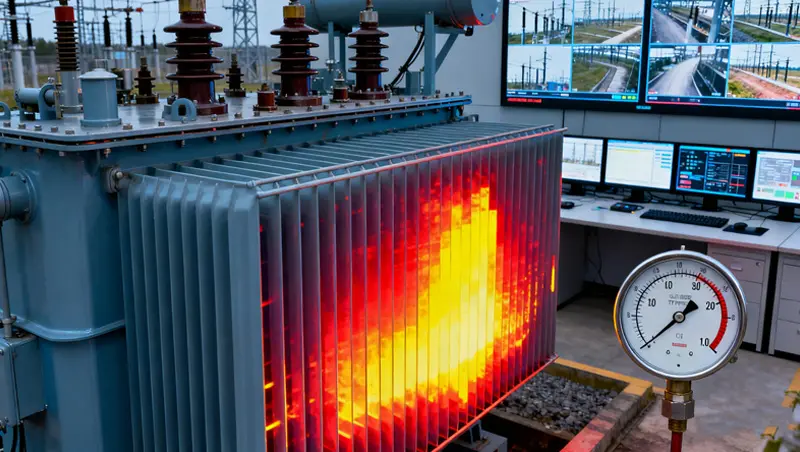

- Monitoring Temperature: Keep an eye on the transformer’s temperature, as overheating can indicate issues with cooling or excessive load.

- Gas Detection: Some transformers are equipped with gas monitoring systems (e.g., Buchholz relays) to detect faults in the oil, such as the formation of gases from internal electrical faults.

- Oil Quality: Regularly inspect the oil for signs of contamination, moisture, or degradation, as poor-quality oil can reduce the transformer’s efficiency and lifespan.

Conclusion

Oil‑filled transformers are widely used in power distribution and industrial applications due to their superior cooling and insulation properties. By understanding how these transformers work, their benefits, types, and maintenance requirements, operators can ensure reliable performance and long-term durability. Regular maintenance, including oil monitoring and proper filling procedures, is essential to extend the life of the transformer and prevent costly failures.

While oil‑filled transformers offer many advantages, they also come with certain risks, particularly related to fire safety and oil leakage. However, with appropriate precautions and good maintenance practices, they remain a popular choice for handling high-capacity electrical loads across various industries.